Latest Product

Big Big Wheels

Concave & Deep Dish Wheels

categories

Our promise remains

Provide mobility options for our customers' wants and needs.

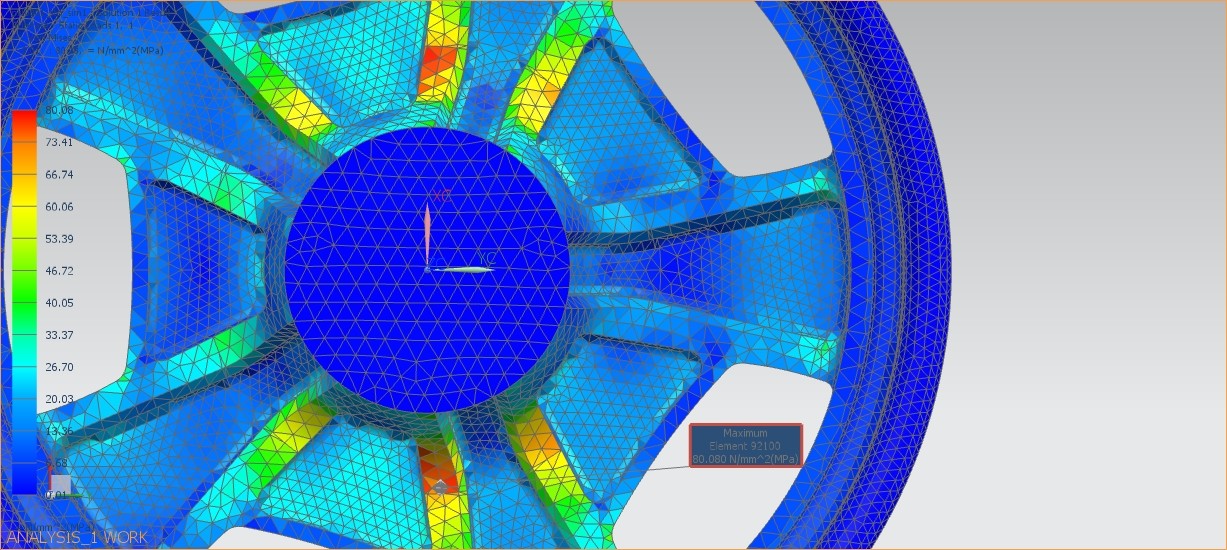

Custom Monoblock Forged Wheels

Custom 2 Piece Wheels

Custom BBS style Wheels

Custom 3 Piece Wheels

Custom Porsche wheels

Concave & Deep Dish Wheels

2-Piece Rims barrel

3-Piece Outer lip & Inner Rims

Monoblock Wheels Blank

Center Disks Blanks

Casting Wheels (inventory)

Flow Form Wheels (inventory)

Off Road Wheels(inventory)

Truck wheels and Bus wheels

BIG BIG WHEELS

Top Products

Brilliant Rays Wheels Trading Co.,Limited

Cases

You can trust on our products then rely on completely.

Categories

Contact Us

| Brilliant Rays Wheels Trading Co.,Limited |

| Building 20, No. 6055 Jinhai Road, Fengxian District, Shanghai, China |

| +86-132-58156783 |

| sales@brwheel.com |

China Custom Monoblock Forged Wheels Supplier. Copyright © 2016 - 2025 Brilliant Rays Wheels Trading Co.,Limited. All Rights Reserved. Developed by ECER